Benefits of SOMs include:

- Simplification of design processes: SOMs provide a ready-made complex circuit that designers can integrate with their hardware, reducing technical challenges and eliminating lengthy hardware design.

- Rapid Development: SOMs allow for quick, pre-certified, pre-tested hardware development, reducing the time-to-market.

- Flexibility and scalability: As project needs change, SOMs allow for easier swaps and upgrades, which is less feasible with SoCs.

A few examples from Ezurio are our Open Standard Modules (OSM), MediaTek Genio powered SMARC SOMs, and NXP’s i.MX powered SMARC SOMs.

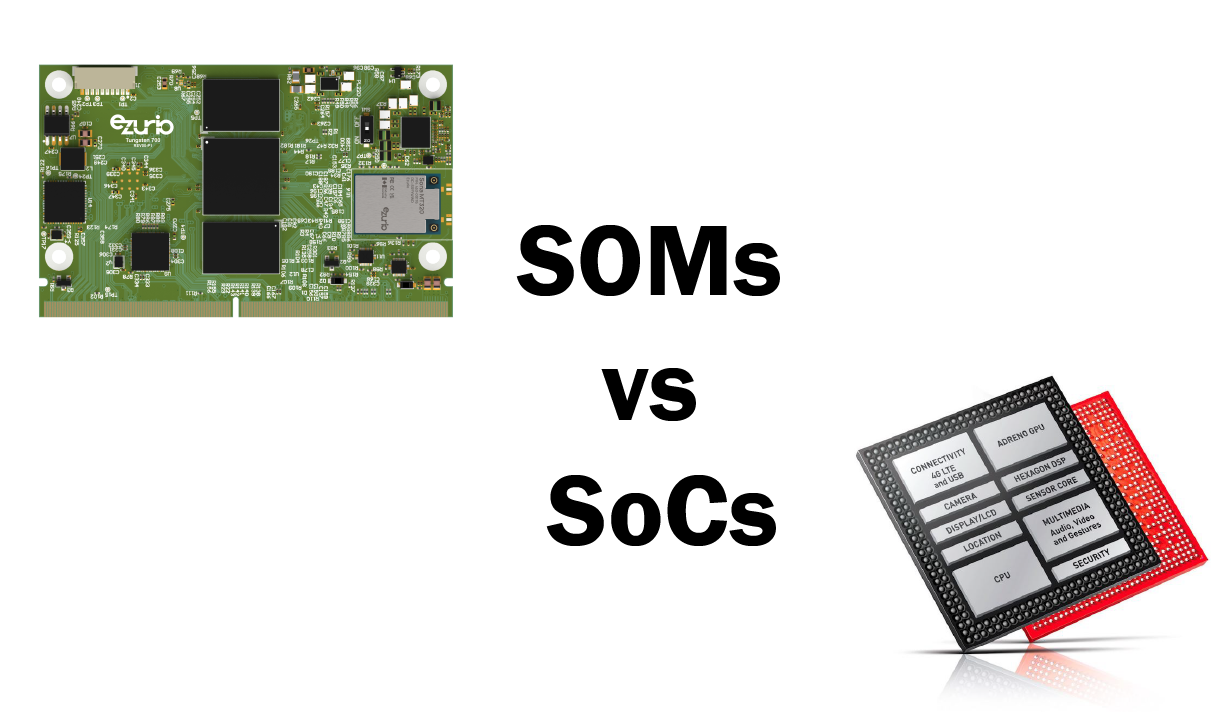

Comparing SOMs and SoCs

Design Flexibility

SOMs offer greater flexibility in design compared to SoCs. This flexibility is particularly beneficial for applications requiring specific customizations not available in standard SoCs. SOMS can be integrated into existing systems without the need for complete ground-up redesigns. This modular approach not only accelerates product development cycles, but also simplifies future upgrades to the system.

For instance, in IoT devices, where the market demands frequent updates, using a SOM can significantly speed up the use of these enhancements. If an advancement in Bluetooth technology offers more reliable connectivity or lower power consumption using the latest Bluetooth 5.4, like Ezurio’s Vela IF820 Series, integrating this into a product using a SOM can be as simple as replacing the existing module with a newer one. This swap causes minimal disruption to the overall product design, saving engineering resources. And experts like Ezurio have additional support services that allow direct access to software and hardware engineers, field application engineers, and documentation like PCB layout patterns. A partner will work with you every step of the way to realize your product design.

Integration vs. Modularity

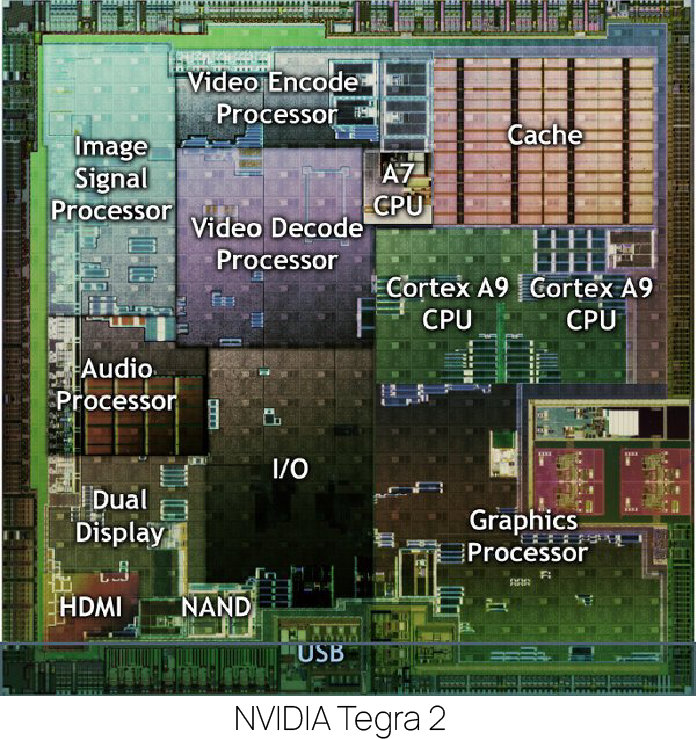

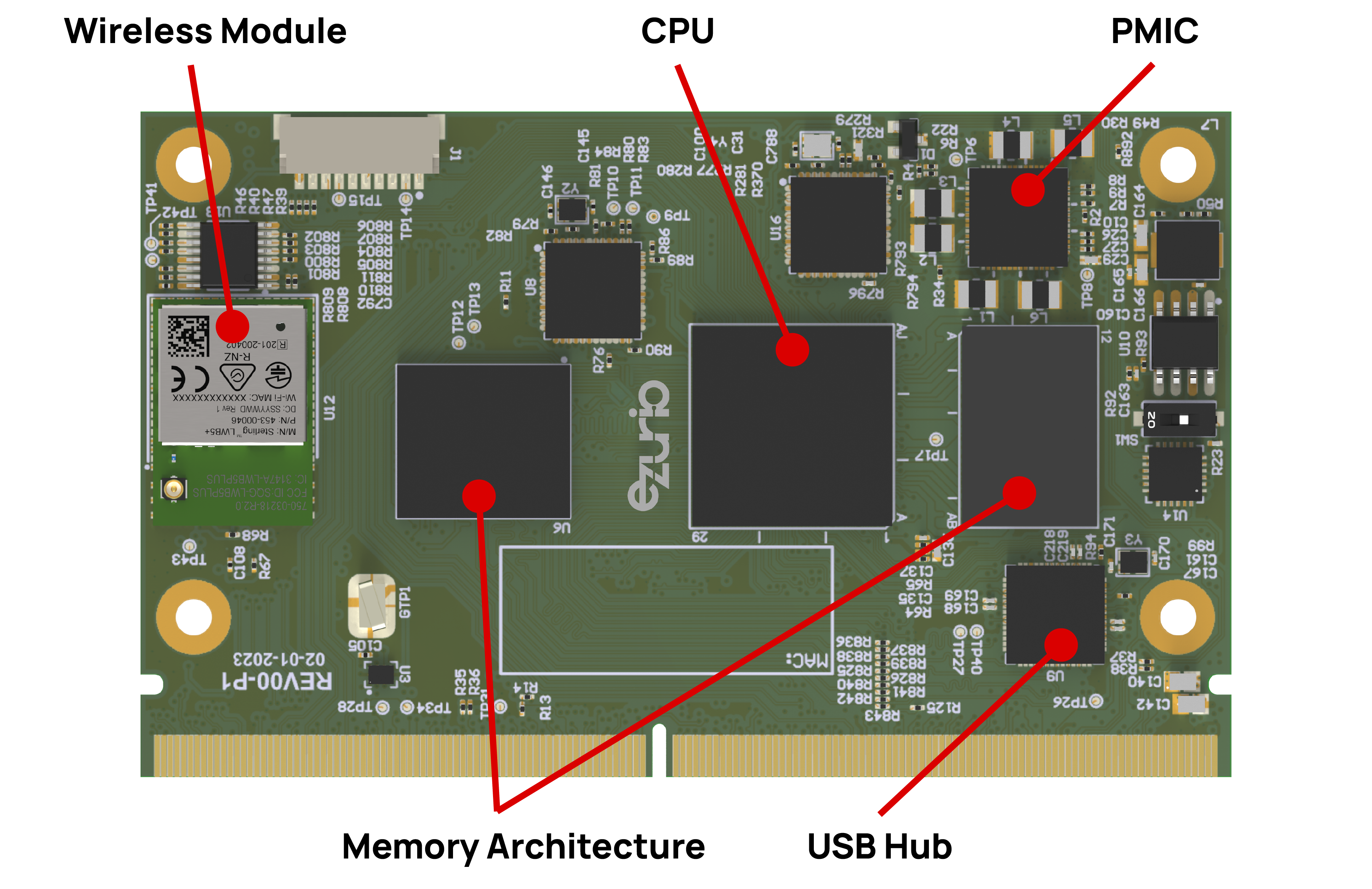

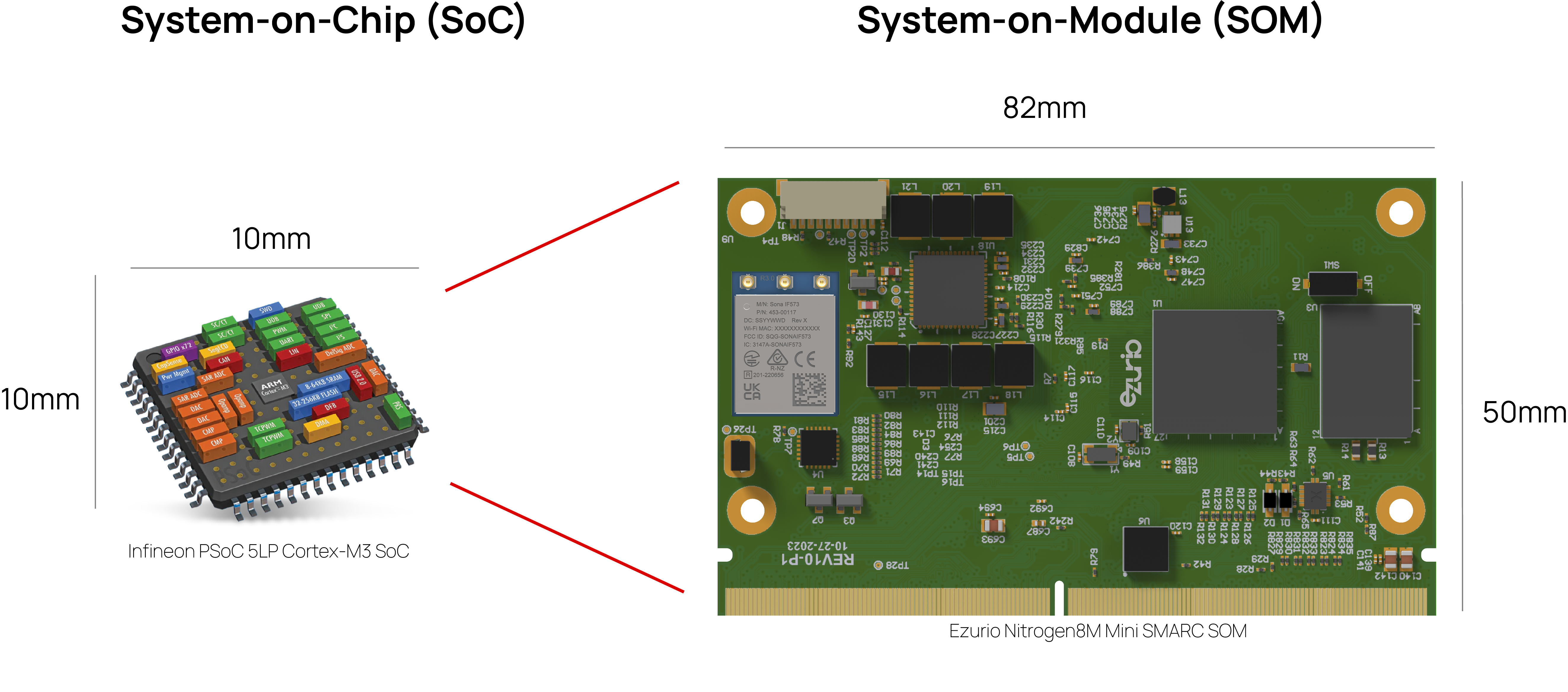

SoCs provide a high level of integration by combining multiple functional components – such as the CPU, GPU, memory, and connectivity modules – into a single chip. This is beneficial for applications where size and power efficiency are critical, such as in mobile devices. However, this integration can limit flexibility because any change to the system often requires a complete redesign of the SoC, which is time-consuming and costly.

On the other hand, SOMs offer a modular approach that increases flexibility without compromising on the benefits of integration. Users can use multiple SOMs with different processors on the same board footprint, which allows applications to be tested on different architectures quickly and easily by swapping the SOMs. This modularity quickens development cycles and reduces time-to-market. It is particularly beneficial in industrial automation, where technology needs can evolve rapidly as these devices have long lifecycles of 10, 15, or even 20 years.

For example, if a new technology or improved component becomes available (such as a high-powered processor like the MediaTek Genio 700) it can be incorporated into an existing design more easily by replacing the SOM than is possible with an SoC. Ezurio’s SOMs use the Smart Mobility Architecture (SMARC) standardized form factor to easily replace an existing SOM with a more advanced one via a standard edge connector, without the need to redesign the entire system.

Cost Implications

Initial development costs of SoCs are very high, as development requires specialized knowledge to integrate all the components (CPU, GPU, memory, etc.) on a single chip. Also, the need for custom design and fabrication processes often involves software tools, prototyping, and testing, which can be expensive, especially for medium-to-low production volumes.

SOMs on the other hand provide a more cost-effective solution in many scenarios, especially where production volumes do not justify the high setup costs of SoC development. Since SOMs come pre-built with essential components and pre-certified with industry standards, they significantly reduce the barriers to entry in terms of both cost and expertise. Pre-certification is crucial as it eliminates the need for individual certification, which can be lengthy and expensive.

Pros and Cons

The following table outlines the advantages and disadvantages of SOM and SoC, providing insights on development time, risk, initial cost, and suitability for different types of applications:

Laird Connectivity is now Ezurio

Laird Connectivity is now Ezurio